China is pushing the boundaries of clean energy infrastructure with its large-scale deployment of Compressed-Air Energy Storage (CAES) systems—offering a cost-effective solution for balancing renewable energy supply and demand. Among its most ambitious projects is the Yingcheng CAES facility, boasting 1,500 MWh of energy capacity.

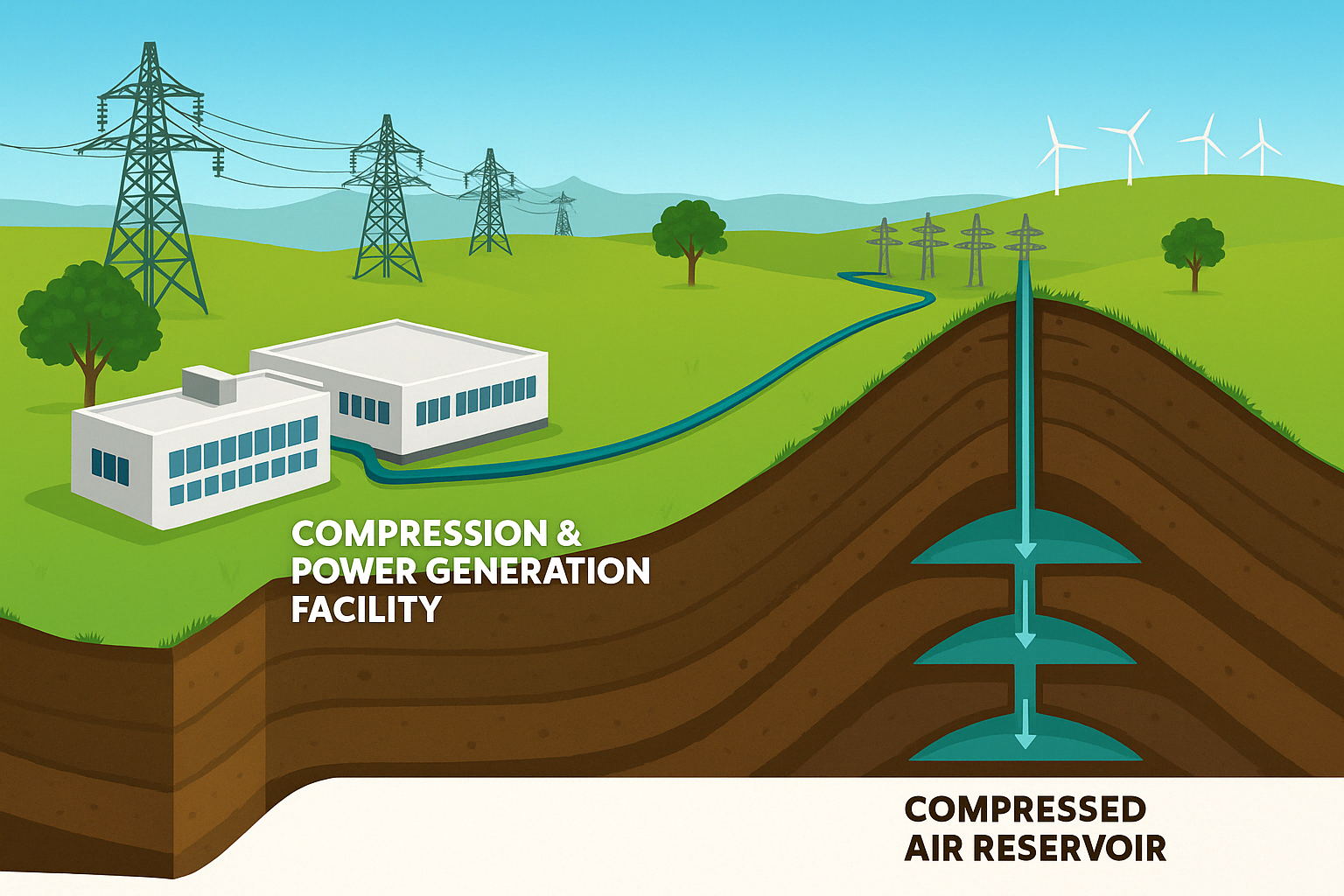

CAES works by using excess renewable electricity (often solar or wind) to compress air and store it in underground caverns or high-pressure tanks. When needed, the compressed air is released, heated, and used to spin turbines, generating electricity on demand.

This method is gaining attention for its scalability, long discharge durations, and relatively low operating costs. For countries like China, where renewable energy curtailment is a growing issue, CAES provides a buffer that stabilizes grids and maximizes clean energy usage.

In the textile industry, particularly in high-production zones across Asia, CAES can support steady power supply during nighttime or monsoon seasons when renewables falter. This ensures consistent factory output, avoids reliance on diesel generators, and contributes to national energy resilience.

CAES also holds promise for export-oriented garment clusters seeking to meet global buyers’ clean energy compliance standards. Its compatibility with large-scale industrial operations, including dyeing, finishing, and spinning, makes it ideal for supporting electrified textile processes.

China’s leadership in CAES is expected to spur global adoption, with feasibility studies underway in India, South Korea, and even parts of Europe. The cost-per-kWh of CAES is projected to fall below lithium-ion battery storage by 2027, unlocking new models for industrial sustainability.

For fashion brands seeking cleaner sourcing partners, integration of CAES into textile parks could soon become a competitive advantage—supporting energy transparency and carbon accounting in line with international sustainability benchmarks.