KERAjet offers three models of digital textile printing machines, each with specifications that vary in terms of printing width, resolution, speed, and other features aimed at enhancing production efficiency in the textile industry. These machines represent a cutting-edge and versatile solution for fabric printing, unlocking new avenues for creative expression. The inclusion of a multi-head system enables experimentation with various ink types, allowing for unique combinations within the same print and the creation of innovative designs on textile products. Simultaneously, these machines are an excellent choice for cost-conscious businesses seeking to minimize investment and maintenance expenses, all while maintaining high product quality. With the capability to house multiple ink types within a single machine, there’s no need for multiple specialized printers for each type. Therefore, KERAjet’s multi-head digital textile printer streamlines production processes, reduces costs, and optimizes workspace by accommodating various printing needs with a single machine.

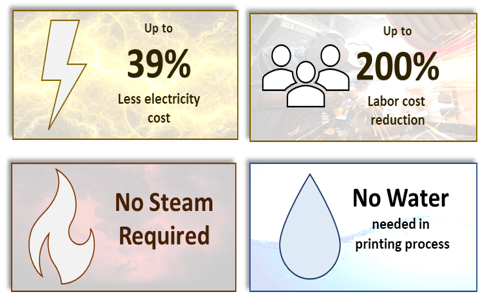

In addition to the advanced technology integrated into the KERAjet textile printers, the process is so optimized that it can result in major energy, water, and other resource savings. The printing process requires no steam and water. Moreover, as the process is fully automated and digitized the labor cost can be saved tremendously. Furthermore, the process does not require washing resulting in huge energy saving as well making the printing process more sustainable.

It is a high productivity and ultra high quality machine, this is due to the K16 (1200 dpi, ultra high quality), K15 (600 dpi, high quality), and K10 (600 dpi, high discharge) heads. It can have up to 12 inks with 28 heads per colour, which means 336 heads and the possibility to include pigmented, reactive, disperse and acid inks.