In the rapidly evolving textile industry, maintaining optimal yarn tension is critical for ensuring high- quality production and minimizing defects. Recognizing this challenge, Eltex, a leader in textile machinery innovation, has developed cutting- edge yarn tension control systems that revolutionize how weavers manage tension throughout the manufacturing process. Their flagship systems, the Eltex ACT-R for rapier machines and the Eltex ACT-G for various machine types, are stand-alone solutions that offer unprecedented precision and control.

Breaking New Ground in Tension Control

The Eltex ACT-R and ACT-G systems are designed to regulate and stabilize yarn tension automatically, eliminating the variations that commonly arise due to differences in yarn package fullness, machine speed, or yarn type. These systems guarantee constant tension levels, whether in rapier weaving machines, air-jet looms, or other specialized machines like sewing or tampon-making devices. Their plug- and-play design allows them to operate independently from the weaving or sewing machines, making installation and integration effortless.

Eltex ACT-R: Perfecting Weft Yarn Tension

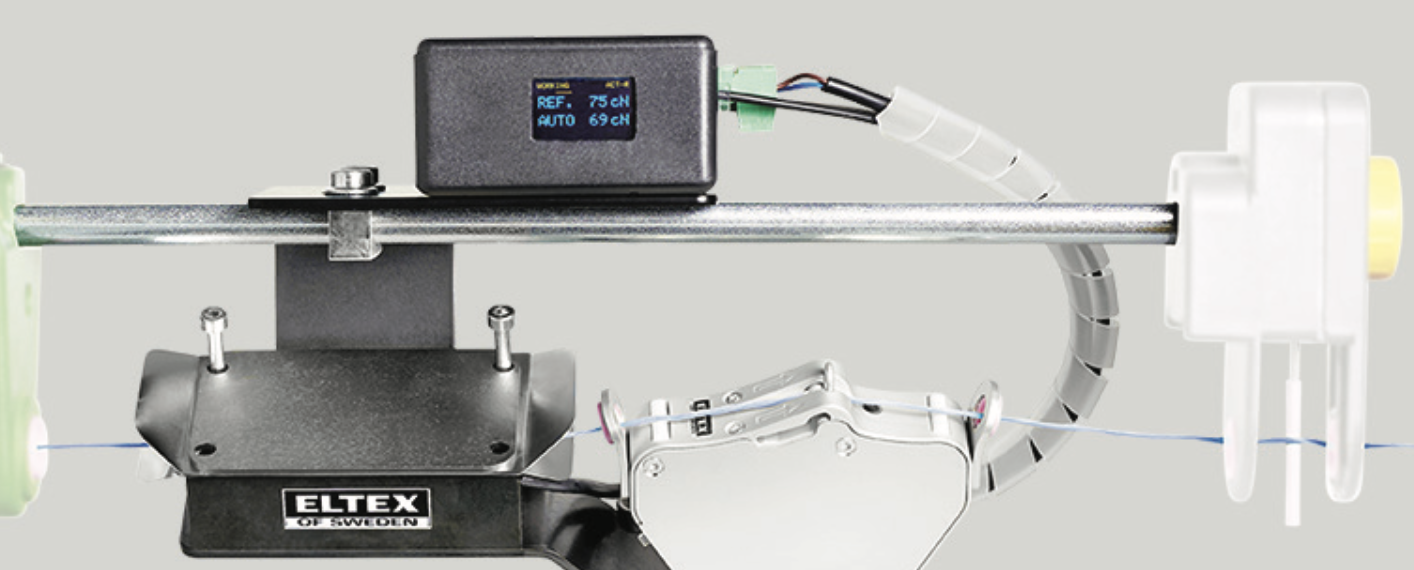

The Eltex ACT-R (Automatic Control of Tension for Rapier machines) offers a breakthrough in controlling weft yarn tension. Installed after the prewinder, it ensures that the tension remains constant, compensating for any irregularities in the yarn package. This system is especially advantageous for technical fabrics and difficult-to-handle yarns, such as recycled materials.

With its ability to automatically adjust tension according to real-time data displayed on a central unit, the ACT-R enhances fabric quality and reduces machine stoppages. Its low- maintenance design, featuring an easy- to-clean smart brake system, ensures that the device can operate with minimal intervention while improving overall process efficiency.

Eltex ACT-G: Versatile Solution Across Machines

The Eltex ACT-G is an equally innovative solution designed for a broader range of machines, including air-jet weaving and sewing machines. It provides accurate and consistent tension control even at low tension levels (less than 10cN), which is essential for handling delicate or complex yarns.

The ACT-G system stabilizes tension throughout the production process, significantly improving fabric quality by reducing the common variations caused by bobbin fullness. This user- friendly system allows operators to set the desired tension through a simple touchscreen interface, making it adaptable for different machine configurations and production needs.

Industry Impact and Future Applications

Eltex’s innovative yarn tension control systems mark a significant leap in textile technology. By automating and perfecting tension control, the ACT-R and ACT-G not only improve fabric quality but also reduce production downtime and waste. As a result, textile manufacturers can enjoy smoother operations, better resource utilization, and enhanced product consistency.