Extended Producer Responsibility (EPR) is emerging as a crucial policy for creating a truly circular fashion economy. The concept of EPR places the obligation on producers to manage the lifecycle of their products, including end-of-life collection, recycling, and disposal. This policy shift is crucial for addressing the massive environmental impact of the textile industry and promoting sustainability.

In our current textile system, most business models are linear: they are based on high volumes of new products, made from virgin resources, which are often used for a short time and then thrown away. Currently, products are not always designed to last and are often hard to recycle.

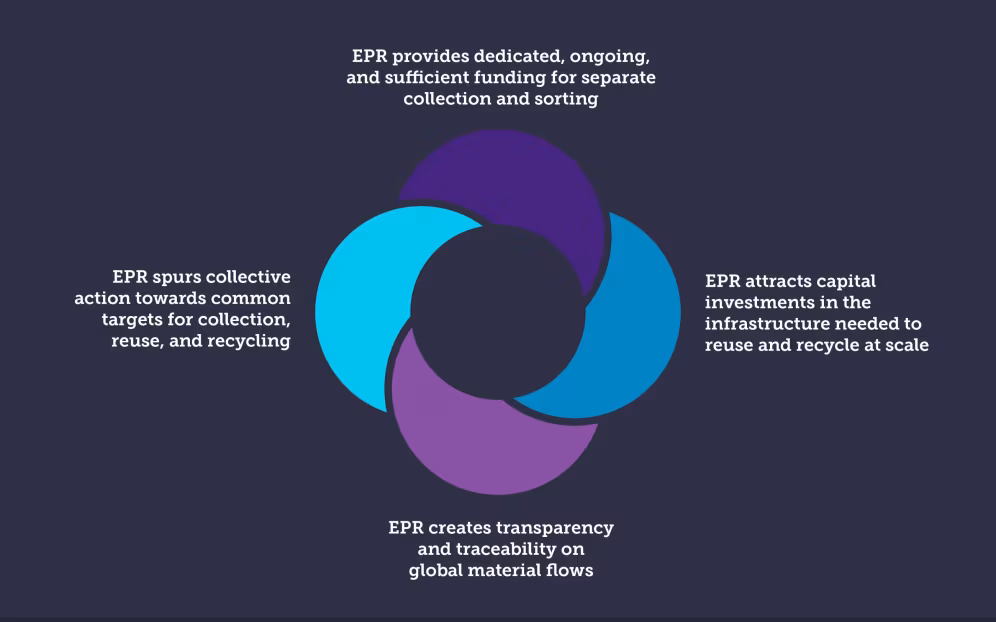

A latest report, titled Pushing the boundaries of EPR policy for textiles (2024), published by Ellen MacArthur Foundation (EMF), said, “A comprehensive circular economy approach is the only solution that can match the scale of this global problem. In this system, businesses contribute to supporting infrastructure in proportion to what they place on the market.”

Separate collection is the only way to keep textiles from ending up in the waste stream or worse, the environment, according to the Ellen MacArthur Foundation. It also said that the collection rates for textiles hover around 14% on average, with up to 86% of textile products being discarded as municipal solid waste. This highlights the urgent need for more efficient collection and recycling systems to manage textile waste sustainably.

While EPR for textiles is gaining traction globally, its implementation varies significantly. In the European Union, countries like France, Hungary, and the Netherlands have already mandated EPR schemes for textiles, aiming to create a cohesive approach to waste management and recycling. However, other regions, such as Australia, Colombia, Ghana, Kenya, California, and New York, are still in the early stages of adopting these policies, often on a voluntary basis.

One of the key challenges in implementing EPR is the lack of a universal definition for textiles and the scarcity of reliable data on collection rates and recycling outcomes. This fragmentation hinders the development of effective EPR schemes and the establishment of clear responsibilities among producers.

Effective EPR schemes must balance economic viability for producers with ambitious environmental goals. This includes setting fees that cover the net cost of collection, sorting, reuse, and recycling without creating perverse incentives to reduce collection volumes.

Additionally, complementary policies, such as the EU’s Ecodesign for Sustainable Products Regulation (ESPR), aim to enhance the quality, durability, and recyclability of textiles, supporting the broader goals of EPR.

The report outlines four primary global goals for optimizing Extended Producer Responsibility (EPR) in the textile industry:

Enhance collection volumes: Expanding and establishing textile collection systems is crucial to divert textiles from mixed waste streams and prevent environmental leakage. Setting targets to increase absolute volumes of separately collected textiles and measuring the relative growth of these volumes will be pivotal.

Boost reuse rates: Maximizing textile reuse before recycling preserves their highest value. The report suggests measuring this objective by assessing the proportion of textiles entering reuse markets relative to those sorted. Efforts and targets should prioritize domestic reuse to extend product life and minimize negative impacts linked to exporting reusable textiles.

Increase recycling rates: Prioritizing textile-to-textile recycling over downcycling and other lower-value applications is essential in EPR strategies. When reuse isn’t feasible due to textile conditions or market availability, sorted textiles should be recycled to retain their material value within the economy.

Decrease waste volumes: Implementing EPR policies aligned with the above objectives should lead to a reduction in textiles reaching their end of life. This reduction should be measured against time-bound targets for waste reduction or diversion, ensuring progress over time.

Fashion brands and retailers are being encouraged to align their product designs with circular economy principles. Otherwise, the effectiveness of funding raised through EPR schemes could diminish if brands and retailers fail to design products for extended use and recyclability after their maximum lifespan.

“Brands and retailers will have a key role to play to support this emerging landscape by investing in reverse logistics infrastructure, and by engaging in long-term sourcing agreements with recyclers in order to support the early stages of commercialization for textile-to-textile recycling,” said the report.

Furthermore, fashion brands and retailers can play a crucial role in ensuring that any new materials they use come from renewable sources and are produced using regenerative agricultural practices.