The European garment industry is undergoing a transformative shift driven by the twin forces of automation and nearshoring. These advancements are poised to revolutionize production processes, bringing significant benefits in terms of efficiency, cost savings, and sustainability.

Nearshoring involves relocating production closer to the end market. For European garment manufacturers, nearshoring means shorter supply chains, reduced transportation costs, and faster response times to market demands. Thus, European manufacturers can better manage inventory, reduce lead times, and respond more quickly to fashion trends.

While nearshoring addresses geographical challenges, automation tackles the intricacies of the garment production process itself. Automation in garment manufacturing encompasses a wide range of technologies, from advanced robotics and computer numerical control (CNC) cutting machines to intelligent software solutions for optimizing production workflows such as:

- Precision and Efficiency with Automated Cutting Machines

Automated cutting machines, including laser and water jet cutters, offer unparalleled precision in fabric cutting. These machines can handle complex patterns and cut through multiple layers of fabric simultaneously, significantly reducing material waste and improving overall efficiency

- Intelligent Fabric Handling

In traditional textile manufacturing, fabric handling tasks account for a significant portion of labor costs. These tasks are often monotonous and physically demanding, such as placing trouser pockets or collars before sewing. Automation addresses these challenges by deploying robots equipped with specialized grippers to handle fabrics with care and precision. These robots can adapt to varying fabric types and shapes, ensuring smooth and efficient handling throughout the production process.

- Robotic Material Handling

Robots and automated systems are increasingly being used for material handling within production facilities. From moving fabric rolls to transporting cut pieces, these systems reduce the reliance on manual labor, enhance workflow efficiency, and minimize the risk of human error. This integration of robotics streamlines the entire production line, enabling manufacturers to achieve higher output with fewer resources.

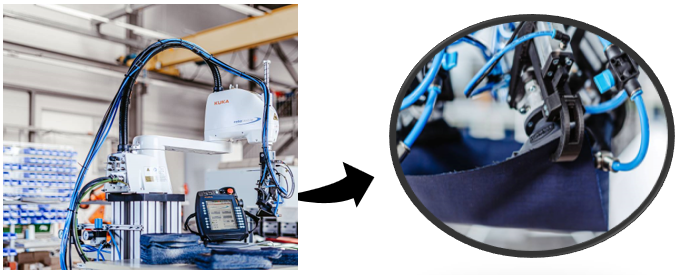

Case Study: Robotextile and KUKA Robotics

Robotextile and KUKA Robotics. Together, they have developed an advanced system solution that combines robotics with intelligent fabric handling technologies. This system addresses industry challenges, such as the variable nature of textiles during processing, by using adaptive gripper technologies and precision robots.

KUKA’s small robots, like those from the KR AGILUS and KR SCARA series, operate efficiently in confined spaces and achieve high precision at fast speeds. These robots ensure consistent manufacturing quality, with capabilities such as handling layers of fabric with integrated sensors for sensitive and precise movements. The result is a highly automated production line that enhances efficiency, reduces costs, and maintains high product quality.

The future of the European garment industry is exemplified by initiatives like the Textile Factory 7.0 (T7) project. This collaborative effort involves academic institutions, industry associations, and leading manufacturers, aiming to reshape the textile industry through innovation and technology. T7 focuses on making textile production more sustainable and bringing it closer to target markets, aligning with the broader goals of nearshoring and automation. By leveraging advanced technologies and strategic geographic shifts, manufacturers can enhance their competitiveness and meet the evolving demands of consumers. As initiatives like the T7 project continue to push the boundaries of innovation, the future of textile production in Europe looks promising, with automation and nearshoring at the forefront of this transformative journey.