Microplastic pollution is one of our most pressing environmental challenges, with the textile industry as a significant contributor. Every wash cycle of synthetic garments releases millions of microplastic fibers into waterways, eventually reaching the oceans and harming marine life. In a breakthrough that could reshape textile manufacturing, researchers at Heriot-Watt University have developed the world’s first visual grading system to identify and reduce microplastic shedding from textiles, promising a greener future for fashion.

Microplastics and Their Growing Environmental Impact

Microplastics—particles less than 5mm in size—severely threaten ecosystems and human health. Textiles, especially synthetic fabrics like polyester, nylon, and acrylic, are among the largest sources of microplastic pollution.

According to the International Union for Conservation of Nature (IUCN), the fashion industry is responsible for 35% of ocean microplastic pollution, amounting to approximately 500,000 tons of synthetic fibers annually. These particles can take hundreds of years to degrade, leaching harmful chemicals into the environment and entering the food chain through marine organisms.

Recent studies also highlight that humans consume up to 50,000 microplastic particles annually, with textiles accounting for a significant share. The urgency for solutions to tackle microplastic shedding has never been greater, and Heriot-Watt’s innovation may be the answer.

Inside the Visual Grading System: A Revolution in Textile Assessment

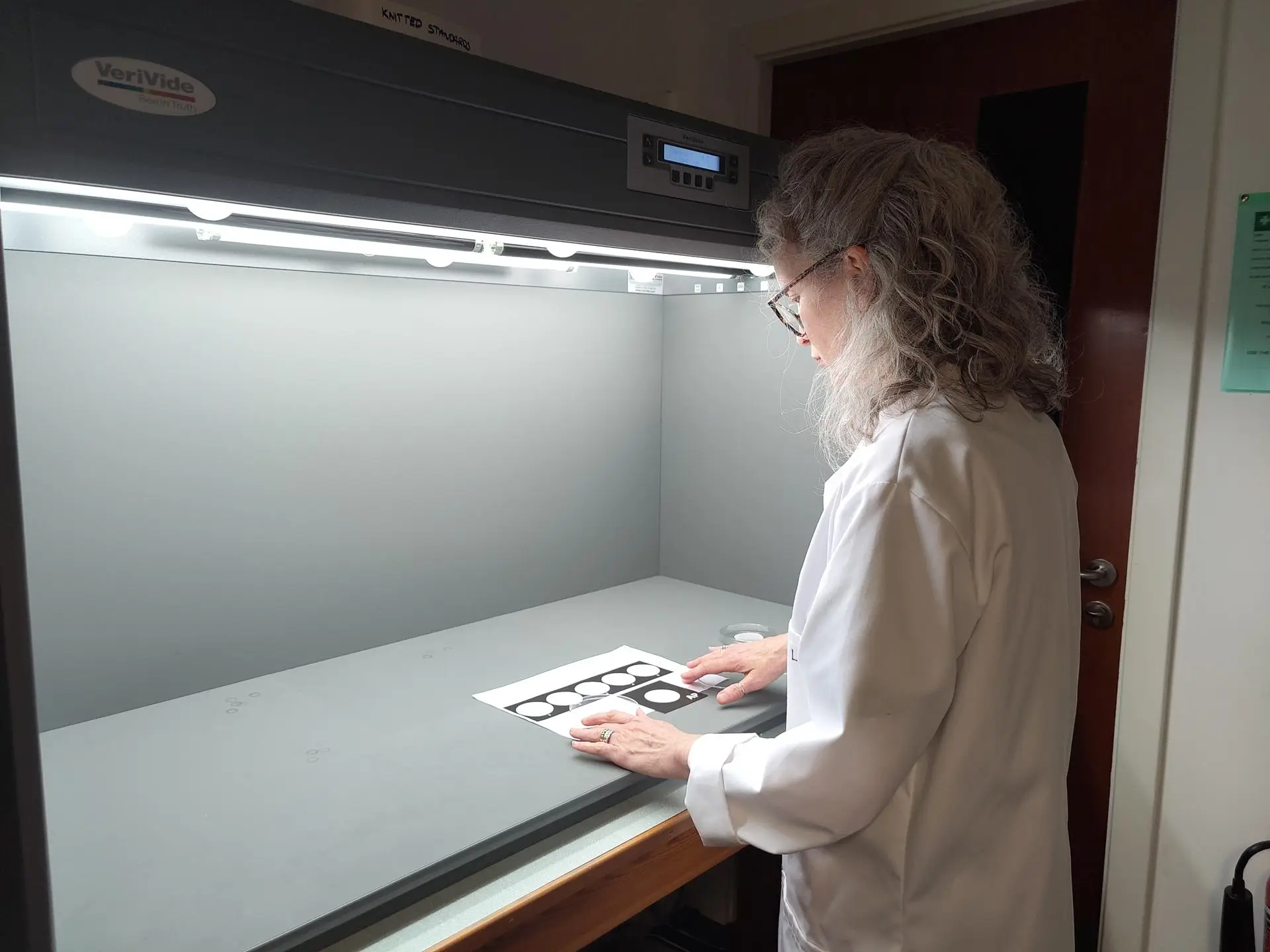

The Heriot-Watt University team, composed of textile scientists and sustainability experts, has developed a visual grading system designed to assess the shedding potential of different fabrics. Unlike conventional tests, this system uses high-resolution microscopy combined with advanced imaging technology to evaluate fibers’ physical characteristics, including texture, weave density, and surface roughness.

Key Features of the System:

- Shedding Quantification: Measures the volume of microfibers released under simulated wear-and-wash conditions.

- Material Assessment: Grades fabrics based on their structural propensity to shed microplastics.

- Durability Insights: Provides manufacturers with guidelines to produce more robust textiles that release fewer fibers over time.

Dr. Sarah Whitman, the project’s lead researcher, explains:

“Our visual grading system offers a practical and scientifically robust way for manufacturers to identify high-shedding fabrics and redesign them for improved sustainability.”

Impact on the Textile and Fashion Industry

Heriot-Watt’s innovation comes at a pivotal time when the fashion industry is under immense pressure to embrace sustainable practices. The visual grading system offers transformative benefits across the textile value chain:

- Improved Material Design: By identifying problematic fabrics, manufacturers can shift towards materials with lower shedding potential or develop innovative fibers that degrade naturally.

- Sustainable Product Development: Designers can incorporate the grading data into their selection process, reducing environmental impact while maintaining fabric performance.

- Enhanced Consumer Trust: Brands adopting this technology can provide transparency through “low-shedding” labels, empowering consumers to make informed eco-friendly choices.

- Policy Alignment: The system aligns with global regulatory movements, such as the European Union’s proposed Textile Strategy, which mandates durability and sustainability in garment production.

Case Study: Industry Adoption in Action

Several global brands are piloting the grading system to integrate it into their production cycles. For instance, a UK-based retailer tested their synthetic garments and discovered that certain items shed 30% more microplastics than their competitors. Armed with this insight, the company redesigned its supply chain, shifting to tighter weaves and incorporating recycled fibers, resulting in a 20% reduction in microplastic emissions.

Such examples highlight how Heriot-Watt’s tool can serve as both a diagnostic and preventative measure in tackling fashion’s environmental footprint.

Beyond Fashion: Applications in Other Industries

While the primary focus is textiles, the potential applications of the grading system extend to industries like:

- Home Furnishings: Curtains, carpets, and upholstery are significant contributors to microplastic shedding in indoor environments.

- Automotive Textiles: Car interiors use synthetic fabrics extensively, and reducing fiber shedding can complement efforts in sustainable vehicle production.

- Industrial Textiles: Items such as geotextiles and filters could benefit from lower shedding materials, enhancing environmental compliance.

Future Developments and Enhancements

Heriot-Watt researchers are now exploring ways to integrate AI and machine learning into the grading system. AI could predict microplastic shedding during the early stages of fabric development, reducing the time and cost of testing. Additionally, partnerships with leading washing machine manufacturers are in discussion to incorporate filtration systems that complement low-shedding textiles.

Call to Action: Industry and Consumer Collaboration

The success of Heriot-Watt’s innovation relies on widespread adoption and collaboration. The textile industry must prioritize:

- Investment in Sustainable R&D: Encourage innovations like low-shedding fibers and biodegradable synthetics.

- Stronger Regulatory Frameworks: Push for policies that incentivize manufacturers to adopt sustainable practices.

- Consumer Awareness Campaigns: Educate consumers about the environmental impact of synthetic garments and promote sustainable washing practices, such as using filter bags or low-temperature cycles to minimize microfiber release.

A Step Towards a Sustainable Future

Heriot-Watt University’s visual grading system is more than a technical innovation; it’s a clarion call for the textile and fashion industries to rethink their approach to sustainability. With microplastic pollution threatening ecosystems and human health, this tool offers a pathway to reduce the environmental toll of textiles while inspiring further innovation.

As Dr. Whitman aptly states:

“The fight against microplastic pollution starts with informed choices. Our grading system is the first step in equipping the industry with the knowledge it needs to create a cleaner, greener future.”

Through collaboration and commitment, this breakthrough could mark the beginning of a new era in sustainable fashion, benefitting both the planet and future generations.