The textile industry has undergone significant transformations over the years, adopting advanced technologies to improve production efficiency, reduce costs, and enhance product quality. As we enter the era of Industry 4.0, intelligent technologies and automation solutions are becoming increasingly prevalent, transforming traditional manufacturing processes.

Pailung’s AI-powered Smart Knitting Automation Solution is an innovative offering that utilizes state-of-the-art technologies to transform the knitting manufacturing process. By integrating artificial intelligence, computer vision, and data analytics, Pailung empowers knit manufacturers to achieve significant advancements in productivity, quality control, and resource optimization.

The heart of Pailung’s Smart Knitting Automation Solution lies in its advanced computer vision technology. Equipped with integrated cameras, the knitting machinery captures high-resolution fabric images during the production process. These images are then analyzed in real-time using advanced algorithms capable of detecting even the most minute defects, such as snags, needle lines, or irregular patterns. This instantaneous defect detection enables swift corrective actions, such as pausing the knitting machine, thereby minimizing the production of flawed fabric and reducing wastage.

Components of Pailung Smart Knitting

Pailung’s Smart Knitting comprises several interconnected systems and technologies that work harmoniously to enable a seamless and intelligent manufacturing environment. These components include:

- Fabric Defect Detection (FDD): The Fabric Defect Detection system utilizes computer vision technology and integrated cameras to detect and identify defects during the knitting process. By promptly identifying defects, manufacturers can take immediate corrective actions, minimizing waste and improving product quality.

- Knitting Fabric Management System (KFMS): KFMS acts as a centralized database for storing knitting detail resources. It allows technicians to access and reproduce fabrics without prior knowledge of their production process. KFMS enables the transfer of know-how from individual technicians to the entire factory, improving operational efficiency and reducing dependency on specific individuals.

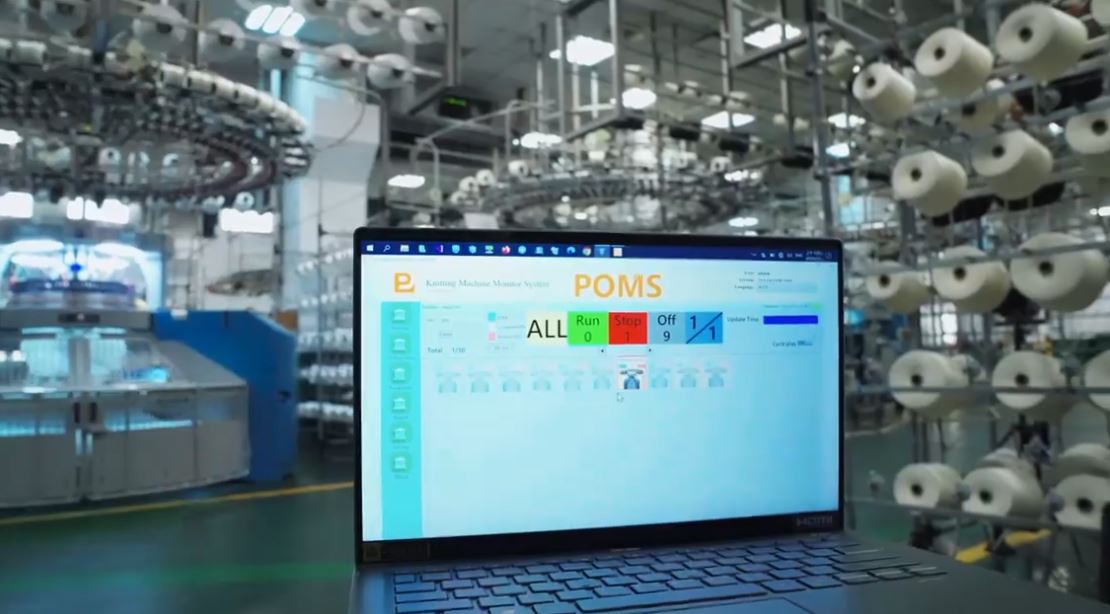

- Pailung Online Management System (POMS): POMS serves as a comprehensive management platform that integrates multiple knitting machines and facilitates remote control and monitoring. This system enables technicians to manage workflows, schedule orders, and monitor machine performance from a centralized dashboard. POMS also connects with FDD and KFMS, providing real-time defect detection, access to fabric resources, and data analysis capabilities.

Advanced Automation Technologies

Pailung’s Smart Knitting solutions leverage advanced automation technologies to enhance the efficiency and productivity of textile manufacturing processes. These technologies include:

- Computer Vision: The integration of computer vision technology in the Fabric Defect Detection (FDD) system enables precise and real-time detection of fabric defects. Sophisticated algorithms analyze the fabric images captured by cameras installed in the knitting machinery, ensuring high accuracy in defect identification.

- Data Analytics: Pailung’s solutions incorporate data analytics capabilities, allowing manufacturers to gain valuable insights from production data. By collecting and analyzing data from knitting machines, the Knitting Fabric Management System (KFMS), and the Pailung Online Management System (POMS), manufacturers can identify patterns, optimize production parameters, and make informed decisions to improve overall operational efficiency.

- Internet of Things (IoT): Pailung’s Smart Knitting solutions embrace the power of IoT to create a connected manufacturing environment. By enabling knitting machines and other equipment to communicate and share data, IoT technology enhances coordination and synchronization, leading to smoother production workflows and reduced downtime.

Real-Time Defect Detection and Control

One of the key features of Pailung’s Smart Knitting solutions is the Fabric Defect Detection (FDD) system. By utilizing computer vision and real-time monitoring, the FDD system identifies defects such as snags, needle lines, or irregular patterns in the fabric during the knitting process. When a defect is detected, the system can automatically pause the knitting machine, allowing technicians to address the issue promptly. This immediate response minimizes the production of defective fabric, reduces waste, and ensures that only high-quality products reach customers.

Seamless Integration and Centralized Management

Pailung’s Smart Knitting offer seamless integration and centralized management through the Knitting Fabric Management System (KFMS) and the Pailung Online Management System (POMS). These systems enable textile manufacturers to streamline operations and optimize resource utilization:

- KFMS: The KFMS serves as a centralized database that stores knitting detail resources. It allows technicians to access and reproduce fabrics with detailed parameters such as machine type, yarn type, specification, tension, and timing. By standardizing fabric production information, KFMS enhances consistency, eliminates reliance on individual expertise, and facilitates efficient fabric reproduction.

- POMS: POMS acts as a comprehensive management platform, offering remote control and monitoring capabilities for multiple knitting machines. Technicians can access real-time production data, schedule orders, and monitor machine performance from a centralized dashboard. POMS integrates with KFMS, enabling technicians to select fabrics, allocate resources, and adjust production parameters seamlessly.

Optimization and Efficiency Enhancement:

Pailung’s Smart Knitting solutions optimize various aspects of textile manufacturing processes, resulting in enhanced efficiency and productivity:

- Resource Utilization: With the integration of KFMS and POMS, technicians can optimize machine resources by accurately scheduling production and maximizing machine utilization. This leads to improved throughput and reduced idle time.

- Intelligent Set-up and Maintenance: Data from KFMS and POMS are used by the Manufacturing Execution System (MES) to automatically set up knitting machines based on fabric parameters. This eliminates the need for manual adjustments, reduces setup time, and ensures consistent production quality. Additionally, MES enables predictive maintenance by monitoring machine performance and detecting anomalies in real-time, allowing proactive maintenance actions to be taken.

- Continuous Improvement: The data collected and analyzed by Pailung’s Smart Knitting solutions facilitate continuous improvement. Manufacturers can identify bottlenecks, optimize production parameters, and implement process enhancements based on data-driven insights. This iterative approach fosters a culture of innovation and drives overall operational excellence.

Benefits of Smart Knitting

Pailung’s Smart Knitting solutions offer numerous benefits to textile manufacturers as they embrace Industry 4.0. Some key advantages include:

- Waste Reduction: The integration of FDD into the knitting process enables real-time defect detection, minimizing waste fabric and reducing financial losses.

- Improved Product Quality: The combination of FDD, KFMS, and POMS ensures better quality control, as defects are detected and corrected promptly. This leads to increased customer satisfaction and minimizes the risk of delivering defective products.

- Know-How Transfer: KFMS allows for the storage and reproduction of fabrics, transferring production knowledge from individual technicians to the entire factory. This ensures consistent quality and enables technicians to produce a wide range of materials without extensive prior knowledge.

- Remote Control and Monitoring: POMS enables technicians to manage multiple knitting machines remotely, streamlining production workflows and enhancing operational efficiency. Real-time monitoring and control facilitate quick response times and minimize machine downtime.

- Predictive Maintenance: Through data analysis and machine performance monitoring, Pailung’s Smart Knitting solutions enable predictive maintenance. This proactive approach reduces unexpected breakdowns and optimizes machine performance, further improving productivity and reducing maintenance costs.