Loepfe’s latest PRISMA software, YarnMaster® 2023-H1 has been updated to the features of new autostart and improved autocorrect, providing the best support and security, user experience, and time and money. The focus of the clever system is to remove unwanted yarn characteristics in the most efficient and data-driven way.

Autostart provides the fastest and safest way to create security settings for new and existing items. Intelligent software automatically generates curves on the basis of yarn quality from the first 100 km/group. This reduces the need to manually traverse all matrices and their curve parameters.

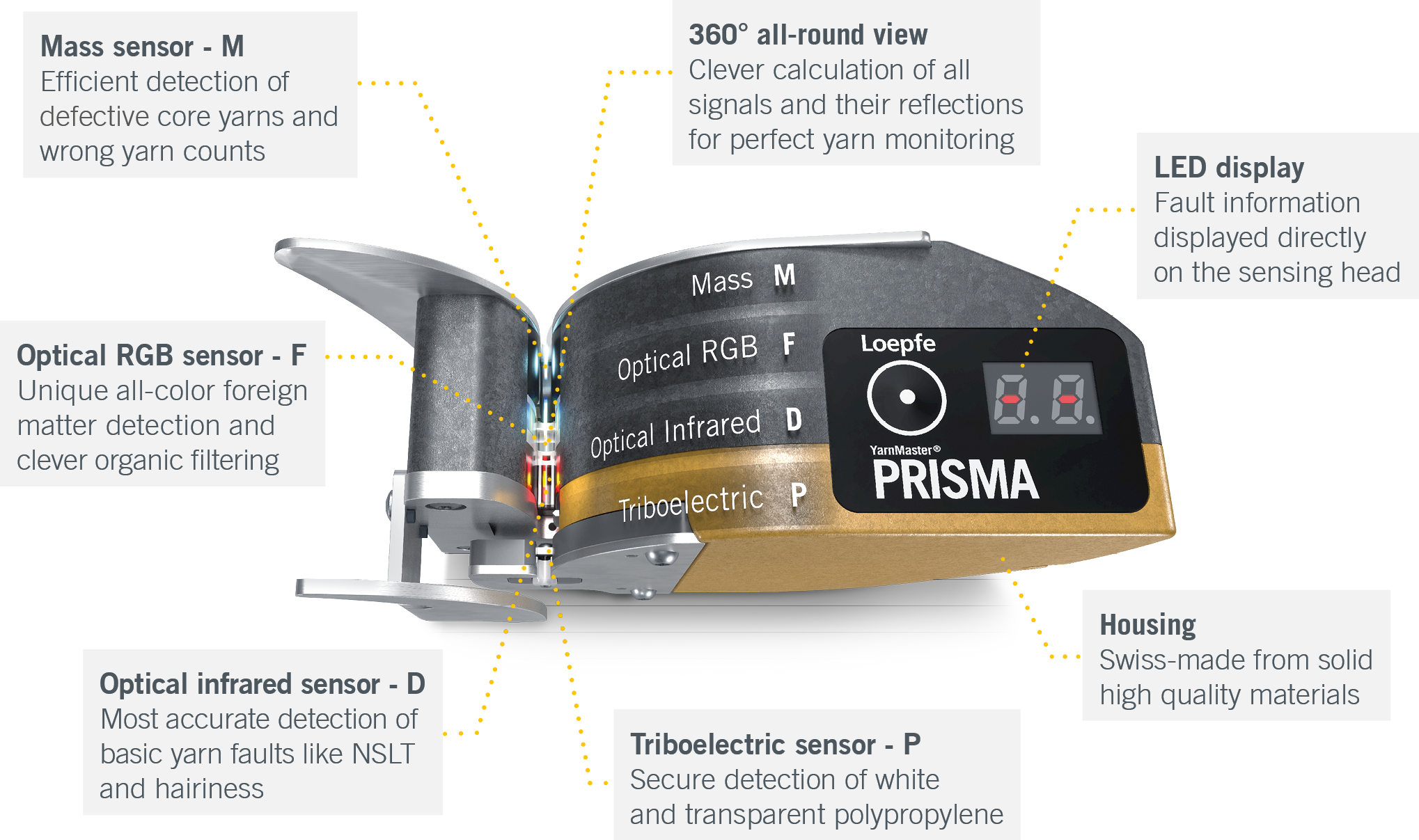

PRISMA provides an array of efficiency-boosting solutions by using cutting-edge technology.

The functionalities of this technology can be classified as below:

- PRISMA MATRIX CLEARING

- PRISMA LENGTH LIMIT ALARM

- PRISMA BOBBIN STARTUP ALARM

- PRISMA CENTRALIZED ALARM MANAGEMENT

PRISMA Matrix cleaning

PRISMA Matrix cleaning is the perfect solution for spinners in order to reduce yarn waste and maximize raw material utilization. Loepfe’s matrix clearing is the foundation of easy and profitable production. It has now been extended to the longest observation lengths on the market. Spinners can be sure that their production is optimized for maximum profitability.

Some key features of Loepfe’s matrix cleaning:

- Classification of every deviation in absolute length

- Informs users about the actual fault deviation at different lengths and limits

- Provides data about the fault distribution and yarn structure even with an open setting

- Longest observation lengths on the market for the following fault types and matrices:

- OffCount (Deviations in Count)- up to 50m

- SFI/D (Hairiness and CV)- up to 80m

- OffColor (Deviations in Color)- up to 50m

Benefits of PRISMA Matrix cleaning: The shorter observation lengths of conventional systems cause cuts immediately when the faults exceed the set curve. Slicing long faults into pieces will significantly downgrade the winding efficiency as well as cause more yarn waste. PRISMA Matrix cleaner removes long faults in the yarn in a single cut and accurately identifies them, providing the most complete picture of the yarn structure in the process. The matrix comes with multiple set points to provide the highest flexibility in setting the clearing curve to ensure the required fabric appearance.

PRISMA Length limit arm

The innovative textile alarm – Length limit alarm – is now available for the matrix of OffCount, SFID, and optionally for OffColor. The Length limit alarm maximizes winding machine and production efficiency with fewer splices and less hard waste. Faults are detected with the “red” clearing curve in the green clearing field until their length touches the “purple” length limit curve. This triggers immediately the Length Limit Alarm and a signal to remove those long faults from the package is sent to the winding machine. This bobbin can then be processed further through the second-level yarn quality process. With the higher efficiency and the possibility of a smooth second-grade process. The length limit curve can be adjusted fully to meet with the spinner’s requirements.

Benefits of PRISMA length limit arm:

- Optimum utilization of raw materials

- Second grade process

- Process optimization

- Better Yarn quality

PRISMA Bobbin startup alarm

Key features:

- This textile alarm detects bobbins with the wrong count, and optionally with the wrong color, within the first wound 11 to 20m.

- The Bobbin startup alarm is preferably used on winding machines with the round magazine to immediately alarm bobbins with different yarn properties.

- The Bobbin startup alarm is automatically active after every bobbin change for the first 20 meters of wound yarn.

Benefits of PRISMA Bobbin startup alarm:

- It provides the fastest detection of faulty bobbins.

- The Bobbin startup alarm will reduce hard waste and improve production efficiency, while also providing the ability to classify cuts and monitor material processes more efficiently.

PRISMA Centralized alarm management

YarnMaster® PRISMA centralized alarm management provides the perfect overview to manage OffStandard bobbins effectively. PRISMA’s centralized alarm management shows all settings of repetitive yarn faults at a glance. This simplifies alarm management and enables the user to set all allowed cut repetitions per bobbin at one central point. This centralized alarm management view is available for every fault type and provides the perfect overview to manage OffStandard bobbins effectively.